Miraah

330 MW SOLAR THERMAL PROJECT IN THE SULTANATE OF OMAN

Petroleum Development Oman (PDO) is the largest oil and gas producer in Oman. It is a joint venture between the government of Oman, Shell, Total and Partex.

Miraah is one of the world’s largest solar plants. The solar thermal facility is harnessing the sun’s energy to produce steam that is used in oil production. The scale of this landmark project underscores the massive market for deploying solar to generate process steam to help industrial users decarbonize their operations.

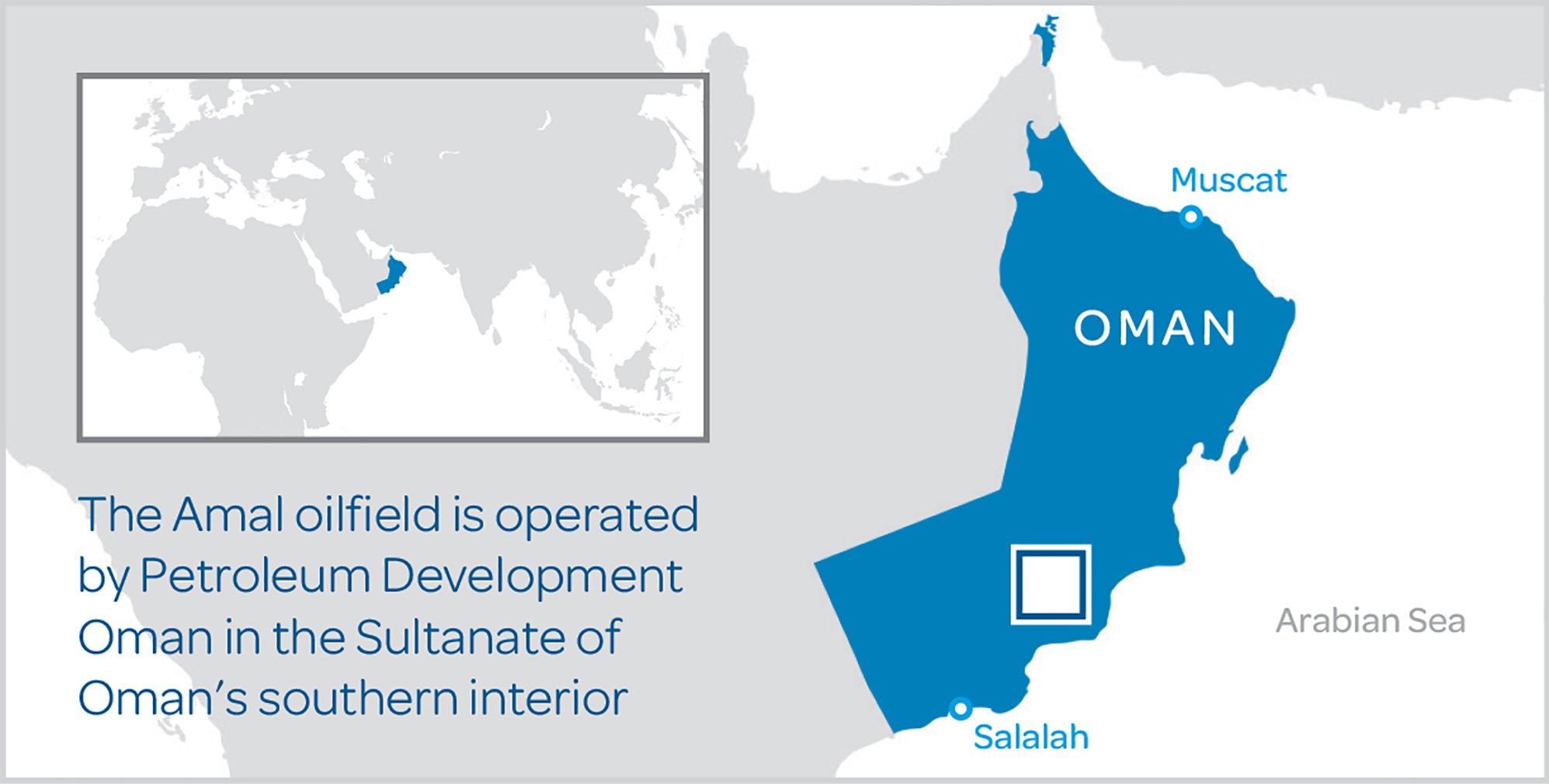

The 330 MWth project will reduce the amount of natural gas used to generate steam for thermal enhanced oil recovery (EOR). In thermal EOR, steam is injected into an oil reservoir to heat the oil, making it easier to pump to the surface. Miraah generates an average of 2,000 tons of solar steam each day, providing a substantial portion of the steam required at the Amal oilfield operated by Petroleum Development Oman (PDO).

The mega project dwarfs all previous solar EOR installations and is more than 33 times larger than the pilot project built by GlassPoint for PDO in 2012. The pilot was completed safely, on time and on budget, and operated successfully through 2017. The pilot exceeded PDO’s expectations for steam delivery and system reliability, paving the way for this significant expansion.

Peak Output: 330 MW Thermal

Energy Output: 445 GWh/year

Daily Steam Output: 2,000 Tons

Solar Field Area: 622,080 m2

Total Project Area: 781,200 m2

Technology: GlassPoint Enclosed Trough

Greenhouse Blocks: 12

Construction Start: 2015

First Steam: 2017

Gas Savings: 1,897,461 Million Btus Per Year

CO2 Emissions Saved: 100,565 Tons Per Year

Technology Provider

GlassPoint is the leader in solar energy for the oil and gas industry. The company’s enclosed trough technology is the only solar thermal system designed specifically for oilfield deployment.

Technology Overview

The enclosed trough solar field uses curved mirrors to focus sunlight onto a pipe filled with water. The concentrated sunlight boils the water to create steam, which is fed directly to the oilfield’s existing steam distribution network. The steam generated is exactly the same quality, temperature and pressure as steam produced by burning natural gas.

A greenhouse protects the solar array from harsh oilfield conditions like wind and dust storms. As a result, GlassPoint can use lightweight and inexpensive components inside the greenhouse. Automated washing reduces costs further and preserves scarce water resources.

Miraah is built using a sequenced deployment process which divides the construction process into standardized, easily repeatable steps. Specialized teams move from block to block completing a specific task—like greenhouse glazing or the installation of our lightweight parabolic mirrors—optimizing the process along the way to speed deployment, control costs and ensure consistent quality.

Status

Miraah is in daily operation delivering solar steam to the Amal oilfield. The first four blocks were completed safely, on schedule and on budget in late 2017.

Economic Benefits

Natural gas not consumed at the field can be used for industrial development, power generation or LNG export

Diversifies Oman’s oil-based economy by establishing a new solar power industry

Creates jobs and training in engineering, construction, operations and administration

Generates in-country value (ICV) through local supply chain development

“Our partnership with GlassPoint and our investment in solar steam generation is a long-term strategy to expand PDO’s heavy oil production and free gas for economic development across Oman.”

RAOUL RESTUCCI

PDO Managing Director